There are a number of reasons for increased interest in aluminium as a foundation for metal powders, and these are mostly related to the properties of the metal as well as the potential for effectiveness in light weight applications.

The properties, in particular, are attractive to many manufacturers. It’s a strong, lightweight metal that offers good impact and corrosion resistance as well as excellent heat conductivity. This means it’s an ideal metal for a wide range of applications, but particularly effective for use in mobility components and parts where specific strength and density performance are paramount.

What about steel?

Where aluminium is growing in popularity, steel has always been the most commonly used powder in the industry, and with good reason. Using iron as a base material, a huge range of powders can be created using different alloying materials depending on the end use of the powder. It’s cost-effective, widely available, and can be customised to suit almost any AM application.

It also remains popular as the industry has been working with it for a long time, so the powders have been developed and optimised over time. Höganäs itself has decades of experience and expertise in these powders, and has helped advance the additive manufacturing industry to be able to serve a wider range of industries and applications.

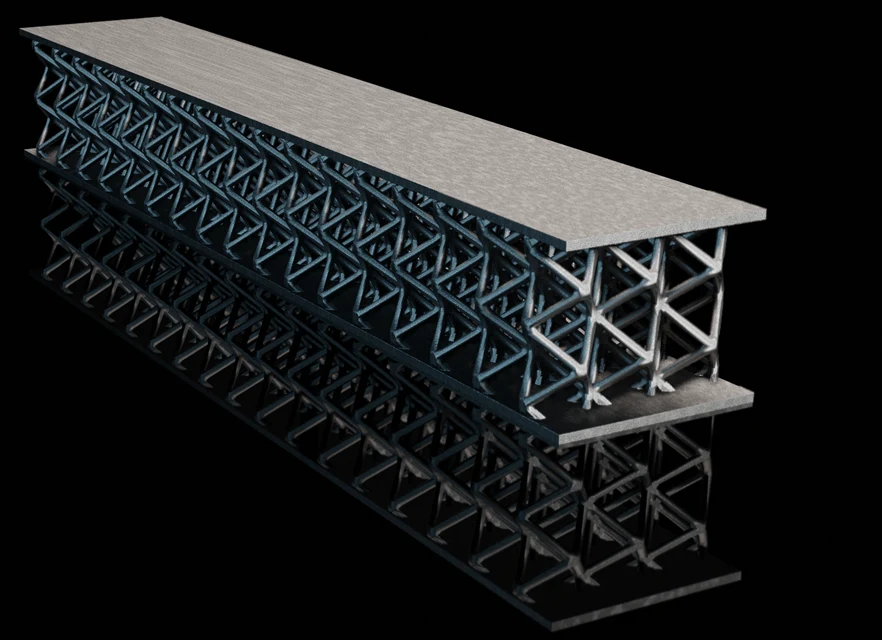

One thing that’s not common knowledge with steel powder, however, is that it can actually be stronger and lighter than aluminium powders in certain circumstances. Höganäs tested two lattice patterns – one made from AlSi10Mg, and the other from maraging steel powder – and the steel could withstand higher maximum loads while weighing less.

These tests were based on a specific lattice pattern, but it further shows that regardless of any material’s base properties, it’s always important to test and analyse to get the right solution for your specific application requirements.

Different materials meet different needs

There is no single best solution when it comes to metal powders, only the best option for each specific set of circumstances. In most cases, there will be a specific steel composition which is optimal, but then aluminium options offer different characteristics that may benefit some application requirements more.

Another benefit to steel is the fact that it is relatively easy and inexpensive to recycle. Of course, this also reduces environmental impact and improves sustainability, which are essential considerations for all industries.

Höganäs has a wide range of powders designed to fit various applications, and we are constantly working on new solutions which can further improve performance, material efficiency, sustainability, and the success of our customers.

#InsightsByHoganas