High-purity powders for 3D printers: Höganäs starts construction of new plant in Germany

“The investment in the million-euro plant will help us to significantly increase our market share for metal powders in the promising segment of 3D printing,” says Höganäs’ site manager Peter Thienel. “In addition, we want to further increase the attractiveness of Höganäs as an employer in Germany and are confident that we can continue to offering our co-workers long-term professional development.”

“The investment in the million-euro plant will help us to significantly increase our market share for metal powders in the promising segment of 3D printing,” says Höganäs’ site manager Peter Thienel. “In addition, we want to further increase the attractiveness of Höganäs as an employer in Germany and are confident that we can continue to offering our co-workers long-term professional development.”

The approval procedure was complex, as the ordinance bundles numerous, once separate, approvals and expert opinions. One of the prerequisites was that plant operation would not cause harm to the environment and that sufficient precautionary measures had been taken.

“We have proven this,” says Sylwia Paulus, responsible for Höganäs’ Health, Safety and Environment (HSE) in Laufenburg. “The reports contained extensive investigations and validations with regard to noise, emissions, fire protection and occupational safety. Ultimately, we fulfilled all the legal requirements within the framework, and beyond.”

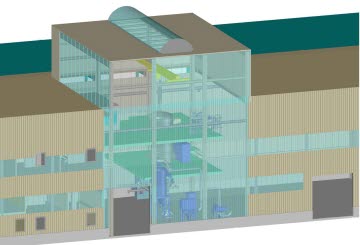

Shortly after receiving the permit, construction work started in the plant building to dismantle stairs, landings, facades and roof. Completion is scheduled for the third quarter of 2020.

More information

For more information please contact,

Ulrika Rask-Lindholm, SVP Communications,

+46 42 33 80 00, ulrika.rask-lindholm@hoganas.com

About HöganäsHöganäs is the world leader in the market for metal powders with a yearly capacity of 500,000 tons. In close cooperation with customers, Höganäs develops tomorrow’s solutions for automotive components, electrical motors, brazing, surface coating, additive manufacturing and sustainable water treatment. Höganäs operates 18 production centres across the globe and has a workforce of 2,500 employees. The turnover for 2018 was 10,360 MSEK. Höganäs, which was founded in 1797, is owned by Lindéngruppen and Wallenberg owned FAM. www.hoganas.com |

||