Surface coating involves the application of a surface material to an existing part or component, with the goal of improving at least one aspect or characteristic, but while this seems like a straightforward thing to do, the impacts can be profound.

Surface coating materials can be effective for an extremely wide range of applications due to the fact that there are so many different materials available. For some applications, a metal alloy coating might achieve the desired effect, while in others it may make more sense to apply a ceramic coating. These coatings can also be applied at different times throughout the lifetime of a part, whether it’s at the manufacturing stage to enhance performance from the start, or as part of a service to extend the component lifetime.

When used in the right way, surface coating will result in a number of benefits, and many of these actually contribute to a more sustainable way of doing business.

Long lasting benefits

Fundamentally, surface coating technology helps improve sustainability by enhancing the durability and repairability of components. Surface coating materials are generally designed to be long-lasting, which in turn reduces the amounts of replacements and repairs required and cuts down consumption. This is crucial for any industry, but particularly for those that rely on heavy-duty equipment to operate at optimal levels for as long as possible, or for those that need to work in harsh environments.

For example, the coatings on tools that are used in mining give essential protection to parts that would otherwise wear down very quickly. This means less downtime, longer periods between maintenance and extended, optimal performance. From a sustainability perspective, this cuts down on waste in terms of replacements, but also reduces emissions associated with the servicing process, as well as ensuring the mining is carried out in a more efficient way.

Another example of surface coatings improving sustainability through durability is with piling vessels – the ships which are used to install off-shore wind farms. These rely on hydraulic systems to stay in the same place regardless of the waves and currents around them, and of course the hydraulic cylinders can be exposed to extreme weather. With the right coatings, these cylinders will operate smoother for longer, ensuring optimal availability for the ships. Good for the business, of course, but also for sustainability as dry-docking procedures or maintenance stops can be less frequent.

More than meets the eye

Durability, of course, is one of the main benefits of surface coating, and also one that has a significant impact on sustainability. However, it’s far from the only improvement. When utilised effectively, surface coating can improve the efficiency of things like jet engine turbines and the internal combustion engine, but how is this possible?

In terms of the modern combustion engine, it’s possible to apply surface coatings to specific parts which helps improve the level of efficiency, thus reducing fuel consumption. These coatings can also help manufacturers to adapt the engines to better suit modern, fossil-free fuels.

When it comes to jet engine turbines, coatings applied using surface coating can achieve huge results. The right coating with high thermal resistance can mean that the turbines can continue to operate efficiently at higher combustion temperatures, which means the fuel can be burnt more efficiently which can, in turn, reduce fuel consumption and CO2 emissions.

These benefits are only really scratching the surface of the potential of surface coating, as it can facilitate a number of improvements, environmental and otherwise, across a broad spectrum of industries. The process is proven to be more environmentally friendly and sustainable, and upon application the surface coatings themselves further improve sustainability. This, in conjunction with performance benefits, is why it’s a growing sector.

Powders and processes

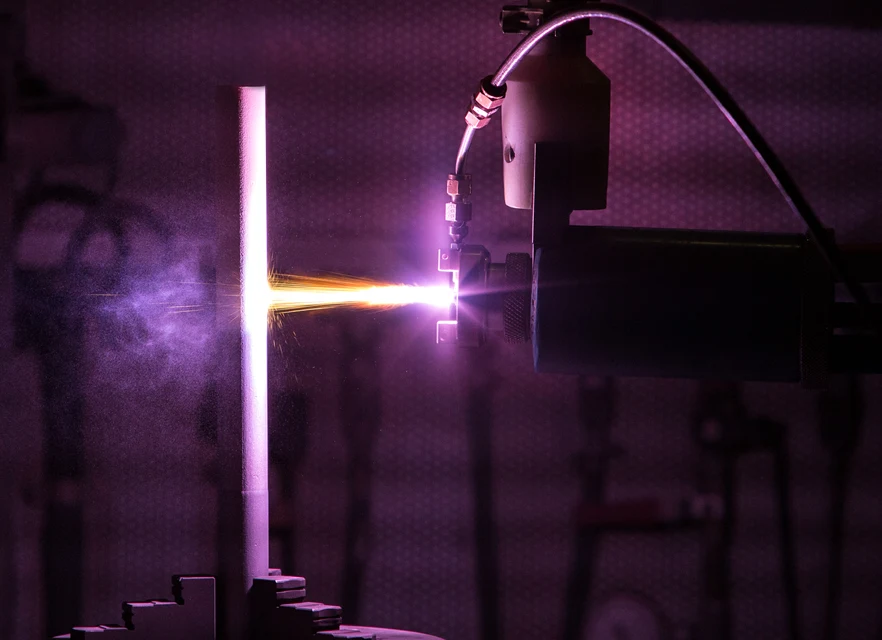

Surface coating is a general term that actually covers a number of coating techniques. There are three common methods - thermal spray, laser cladding, and plasma transferred arc welding - and they all have different benefits and use cases which depend on the application of the finished product. This is in addition to multiple surface coating materials, so between the material and the method, there are countless combinations that can be tailored to very specific needs.

Höganäs is the world leader in metal powders, and has a range of products designed for optimal performance with surface coating. We can help you to find your ideal process and powder combination, and we can offer guidance around how to achieve the best possible performance while reducing environmental impact. Get in touch with our team to find out more.