レーザクラッディング用粉末

Surfit® コバルト(Co)系粉末

Surfit 2528-00 | Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo | 150/53 µm

粒度:150/53 μm

化学成分:Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo

粉末タイプ: ガスアトマイズ法

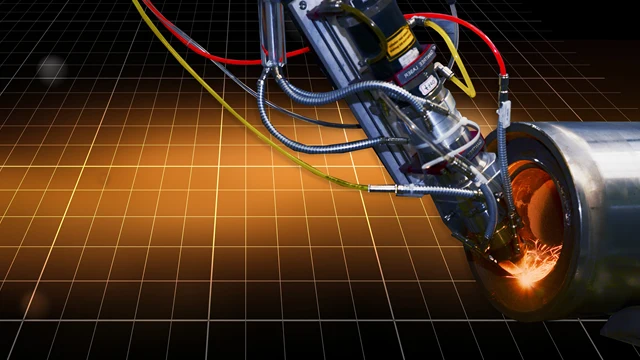

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 2537-00 | Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W | 150/53 µm

粒度:150/53 μm

化学成分:Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 2537-10 | Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W | 150/53 µm

粒度:150/53 μm

化学成分: Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 2540-00 | Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W | 150/53 µm

粒度:150/53 μm

化学成分: Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 2541-00 | Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W | 150/53 µm

粒度:150/53 μm

化学成分:Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 2541-10 | Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W | 150/53 µm

粒度: 150/53 µm

化学成分: Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 2548-00 | Co 2.3C 1.2Si 30Cr 1Fe 13W | 150/53 µm

粒度: 150/53 µm

化学成分: Co 2.3C 1.2Si 30Cr 1Fe 13W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit ST 156 | Co 1.6C 1.1Si 27.5Cr 1.8Ni <1Mo 4W | 150/45 µm

粒度: 150/45 µm

化学成分: Co 1.6C 1.1Si 27.5Cr 1.8Ni <1Mo 4W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit HB 400 | Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo | 150/53µm

粒度: 150/53 µm

化学成分:Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit HB 400 | Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo | 150/63µm

粒度: 150/63 µm

化学成分:Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit HGMET LFE | Co <0.1C 0.3Si 0.7Fe 27Cr 9.5Ni 5Mo 0.8Mn 2W | 150/53 µm

粒度: 150/53 µm

化学成分:Co <0.1C 0.3Si 0.7Fe 27Cr 9.5Ni 5Mo 0.8Mn 2W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 2748-00 | Co 2.3C 1.2Si 30Cr 1Fe 13W | 212/63 µm

粒度: 212/63 µm

化学成分: Co 2.3C 1.2Si 30Cr 1Fe 13W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Amperweld® 硬質相粉末

Amperweld CTC | C 4% | 150/53 µm

Particle size: 150/53 µm

Chemistry: C 4%

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld CTC | C 4% | 106/36 µm

Particle size: 106/36 µm

Chemistry: C 4%

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld SCTC | C 4% | 150/53 µm

Particle size: 150/53 µm

Chemistry: C 4%

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld MTC | C 4.3% – 5.2% | 150/53 µm

Particle size: 150/53 µm

Chemistry: C 4.3% – 5.2% (depending on particle size)

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld MTC | C 4.3% – 5.2% | 180/53 µm

Particle size: 180/53 µm

Chemistry: C 4.3% – 5.2% (depending on particle size)

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld VC | 160/63 µm

Particle size: 160/63 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld VC | 90/45 µm

Particle size: 90/45 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld VC | 45/5 µm

Particle size: 45/5 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld TiC | 200/106 to 45/5 µm

Particle size: 200/160 to 45/5 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld CrB | 400/63 µm

Particle size: 400/63 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld CrB2 | 400/63 µm

Particle size: 400/63 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit® 硬質相粉末

Surfit® Ni 自溶性合金 + カーバイド混合

Höganäs は、ニッケル自溶性(SF)合金とタングステン・カーバイドの幅広い種類のSurfit混合物粉末を提供します。

ニッケル自溶性合金の幅広いポートフォリオと、さまざまなタングステンカーバイドを組み合わせることで、用途の要件に合わせて調合できます。

- ニッケル自溶性合金

- Amperweld® タングステンカーバイド

- Amperweld CTC - キャストタングステンカーバイド

- Amperweld SCTC - 球状タングステンカーバイド

- Amperweld MTC - Macroline タングステンカーバイド

- Amperit® タングステンカーバイドコバルト

- Amperit 519 WC-Co 88-12

- Amperit 526 WC-Co 83-17

用途に合ったSurfit混合物粉末は、 Höganäs 営業担当者にお問い合わせください。

粒度: -

化学成分: -

粉末タイプ: 混合

通常使用される成膜技術:フレーム溶射,HVOF,レーザークラッディング,粉体プラズマアーク溶接(PTA),粉末溶接

Rockit® 鉄(Fe)系金属粉

Rockit 401 | Fe 0.15C 18Cr 2.5Ni 0.5Mo <4 その他 | 180/53 μm

粒度: 180/53 µm

化学成分: Fe 0.15C 18Cr 2.5Ni 0.5Mo <4 その他

粉末タイプ: 水アトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Rockit 431SR | Fe 0.15C 16Cr 1.75Ni <5 その他 | 180/53 µm

粒度: 180/53 µm

化学成分: Fe 0.15C 16Cr 1.75Ni <5 その他

粉末タイプ: 水アトマイズ法

通常使用される成膜技術:レーザクラッディング

|

備考:

|

||

Rockit 606 | Fe 2C 0.9Si 5Cr 6V <4 その他 | 180/53 µm

粒度: 180/53 µm

化学成分: Fe 2C 0.9Si 5Cr 6V <4 その他

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザクラッディング

|

備考:

|

||

Surfit® 鉄(Fe)系金属粉

Surfit 3.33 LOWC | Fe 0.2C 1.3Si 28Cr 16Ni 4.5Mo 1Mn | 150/45 µm

粒度: 150/45 µm

化学成分: Fe 0.2C 1.3Si 28Cr 16Ni 4.5Mo 1Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザクラッディング

|

備考:

|

||

Surfit 3533-00 | Fe 1.75C 1.3Si 28Cr 16Ni 4.5Mo 0.8Mn | 150/53 µm

粒度:150/53 μm

化学成分:Fe 1.75C 1.3Si 28Cr 16Ni 4.5Mo 0.8Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 3533-10 | Fe 2.1C 1.2Si 28Cr 11.5Ni 5.5Mo 1Mn | 150/53 µm

粒度:150/53 μm

化学成分: Fe 2.1C 1.2Si 28Cr 11.5Ni 5.5Mo 1Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 309L | Fe <0.03C 0.5Si 23Cr 13Ni 1Mn | 150/53 µm

粒度:150/53 μm

化学成分: Fe <0.03C 0.5Si 23Cr 13Ni 1Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

Surfit 316L HSI | Fe <0.03C 1.6Si 17Cr 12Ni 2.5Mo 1.5Mn | 150/53 µm

粒度:150/53 μm

化学成分: Fe <0.03C 1.6Si 17Cr 12Ni 2.5Mo 1.5Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 410L | Fe <0.03C 0.5Si 12.5Cr 0.1Mn | 150/53 µm

粒度:150/53 μm

化学成分: Fe <0.03C 0.5Si 12.5Cr 0.1Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 420S | Fe 0.25C 0.5Si 13Cr <1Ni 1.2Mn | 125/45 µm

粒度: 125/45 µm

化学成分:Fe 0.25C 0.5Si 13Cr <1Ni 1.2Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 420S | Fe 0.25C 0.5Si 13Cr <1Ni 1.2Mn | 180/53 µm

粒度: 180/53 µm

化学成分:Fe 0.25C 0.5Si 13Cr <1Ni 1.2Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 431L HC | Fe 0.2C 0.75Si 16Cr 1.8Ni <1Mn | 150/53 µm

粒度:150/53 μm

化学成分:Fe 0.2C 0.75Si 16Cr 1.8Ni <1Mn

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit H13 | Fe 0.35C 1Si 5Cr 1.5Mo 0.3Mn 1V | 150/53 µm

粒度:150/53 μm

化学成分:Fe 0.35C 1Si 5Cr 1.5Mo 0.3Mn 1V

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit®ニッケル (Ni) 系粉末

Surfit 1515-00 | Ni <0.06C 2Si 1.1B 0.5Fe 20Cu | 150/53 µm

粒度:150/53 μm

化学成分: Ni <0.06C 2Si 1.1B 0.5Fe 20Cu

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1520-00 | Ni <0.06C 2.3Si 1.4B 0.4Fe | 150/53 µm

粒度:150/53 μm

化学成分:Ni <0.06C 2.3Si 1.4B 0.4Fe

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1525-30 | Ni 0.1C 2.6Si 1B 1.9Fe 3.3Cr 0.4Al | 150/53 µm

粒度:150/53 μm

化学成分: Ni 0.1C 2.6Si 1B 1.9Fe 3.3Cr 0.4Al

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1532-40 | Ni 0.15C 3.4Si 1.2B 3.1Fe 7Cr | 150/53 µm

粒度:150/53 μm

化学成分:Ni 0.15C 3.4Si 1.2B 3.1Fe 7Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1535-30 | Ni <0.07C 3Si 1B 1Al 2.4Fe 5.6Cr | 150/53 µm

粒度:150/53 μm

:Ni <0.07C 3Si 1B 1Al 2.4Fe 5.6Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1538-40 | Ni <0.07C 3Si 2.3B <0.8Fe | 150/53 µm

粒度:150/53 μm

化学成分:Ni <0.07C 3Si 2.3B <0.8Fe

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1540-00 | Ni 0.25C 3.5Si 1.6B 2.5Fe 7.5Cr | 150/53 µm

粒度:150/53 μm

化学成分: Ni 0.25C 3.5Si 1.6B 2.5Fe 7.5Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1545-00 | Ni 0.35C 3.6Si 1.9B 2.7Fe 9Cr | 150/53 µm

粒度:150/53 μm

化学成分: Ni 0.35C 3.6Si 1.9B 2.7Fe 9Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1550-00 | Ni 0.45C 3.8Si 2.3B 2.9Fe 11Cr | 150/53 µm

粒度:150/53 μm

化学成分: Ni 0.45C 3.8Si 2.3B 2.9Fe 11Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1555-20 | Ni 0.5C 4Si 3.4B 2.8Fe 16Cr 3Mo 3Cu | 150/53 µm

粒度: 150/63 µm

化学成分:Ni 0.5C 4Si 3.4B 2.8Fe 16Cr 3Mo 3Cu

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1559-40 | Ni <0.06C 3Si 2.9B | 150/53 µm

粒度:150/53 μm

化学成分: Ni <0.06C 3Si 2.9B

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1560-00 | Ni 0.75C 4.3Si 3.2B 3.8Fe 14.8Cr | 150/53 µm

粒度:150/53 μm

化学成分: Ni 0.75C 4.3Si 3.2B 3.8Fe 14.8Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 1562-00 | Ni 0.6C 3.7Si 2.8B 3.5Fe 14.3Cr 9.5W | 150/53 µm

粒度:150/53 μm

化学成分:Ni 0.6C 3.7Si 2.8B 3.5Fe 14.3Cr 9.5W

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit 5510-40 | Ni 5Al | 150/53 µm

粒度:150/53 μm

化学成分:Ni 5Al

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

Surfit IN 625 | Ni <0.03C 0.4Si 0.75Fe 21.5Cr 9Mo 3.7Nb | 125/45 µm

粒度: 125/45 µm

化学成分: Ni <0.03C 0.4Si 0.75Fe 21.5Cr 9Mo 3.7Nb

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit IN 625 | Ni <0.03C 0.4Si 0.75Fe 21.5Cr 9Mo 3.7Nb | 150/45 µm

粒度: 150/45 µm

化学成分: Ni <0.03C 0.4Si 0.75Fe 21.5Cr 9Mo 3.7Nb

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit IN 625 | Ni <0.03C 0.4Si 0.75Fe 21.5Cr 9Mo 3.7Nb | 150/53 µm

粒度:150/53 μm

化学成分: Ni <0.03C 0.4Si 0.75Fe 21.5Cr 9Mo 3.7Nb

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit IN 625 | Ni <0.03C 0.4Si 0.75Fe 21.5Cr 9Mo 3.7Nb | 180/63 µm

粒度: 180/63 µm

化学成分: Ni <0.03C 0.4Si 0.75Fe 21.5Cr 9Mo 3.7Nb

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit HAST C276-M | Ni 0.12C 0.5Si 3Fe 15.5Cr 16Mo 4.5W 1.2Mn 0.5V | 150/53 µm

粒度:150/53 μm

化学成分: Ni 0.12C 0.5Si 3Fe 15.5Cr 16Mo 4.5W 1.2Mn 0.5V

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:レーザークラッディング法、粉体プラズマアーク溶接(PTA)

|

備考:

|

||

Surfit® Ni 自溶性合金 + カーバイド混合

Höganäs は、ニッケル自溶性(SF)合金とタングステン・カーバイドの幅広い種類のSurfit混合物粉末を提供します。

ニッケル自溶性合金の幅広いポートフォリオと、さまざまなタングステンカーバイドを組み合わせることで、用途の要件に合わせて調合できます。

- ニッケル自溶性合金

- Amperweld® タングステンカーバイド

- Amperweld CTC - キャストタングステンカーバイド

- Amperweld SCTC - 球状タングステンカーバイド

- Amperweld MTC - Macroline タングステンカーバイド

- Amperit® タングステンカーバイドコバルト

- Amperit 519 WC-Co 88-12

- Amperit 526 WC-Co 83-17

用途に合ったSurfit混合物粉末は、 Höganäs 営業担当者にお問い合わせください。

粒度: -

化学成分: -

粉末タイプ: 混合

通常使用される成膜技術:フレーム溶射,HVOF,レーザークラッディング,粉体プラズマアーク溶接(PTA),粉末溶接

お問い合わせ

Sales & Technical support

プライバシー保護に関する方針

私は、ヘガネスが、私と連絡をとる目的で、私の個人データを利用することに同意します。 また、私の連絡先情報をニュースレターやその他関連情報といったマーケティング目的に使用することに同意します。 データが第三者と共有されることはありません。 また、16歳以上であることを認めます。

個人情報の取扱いに関する詳細は、弊社のプライバシー保護方針でご確認いただけます。