特許取得済みのステンレス基ろう付け材料、Höganäs BrazeLet ® F300は、銅を全く含まない状態でオイルクーラーのろう付けが出来ます。エンジンオイルへの銅の浸出がないため、オイルの寿命を延ばしエンジンの摩耗を最小限におさえることができます。さらに利点として、完全にステンレス鋼だけで製品を作れるため、再利用がより容易で、すべてのステップでサステナビリティーが促進されます。Höganäs 独自開発のペーストは、ローラコーティング用に特別に配合されており、最大 20m/ 分のベルト速度で均一なコーティング層を生成するローラコーティングを使用して、油冷却器タービュレータに効率的に塗布できます。

Höganäs オイルクーラーソリューション

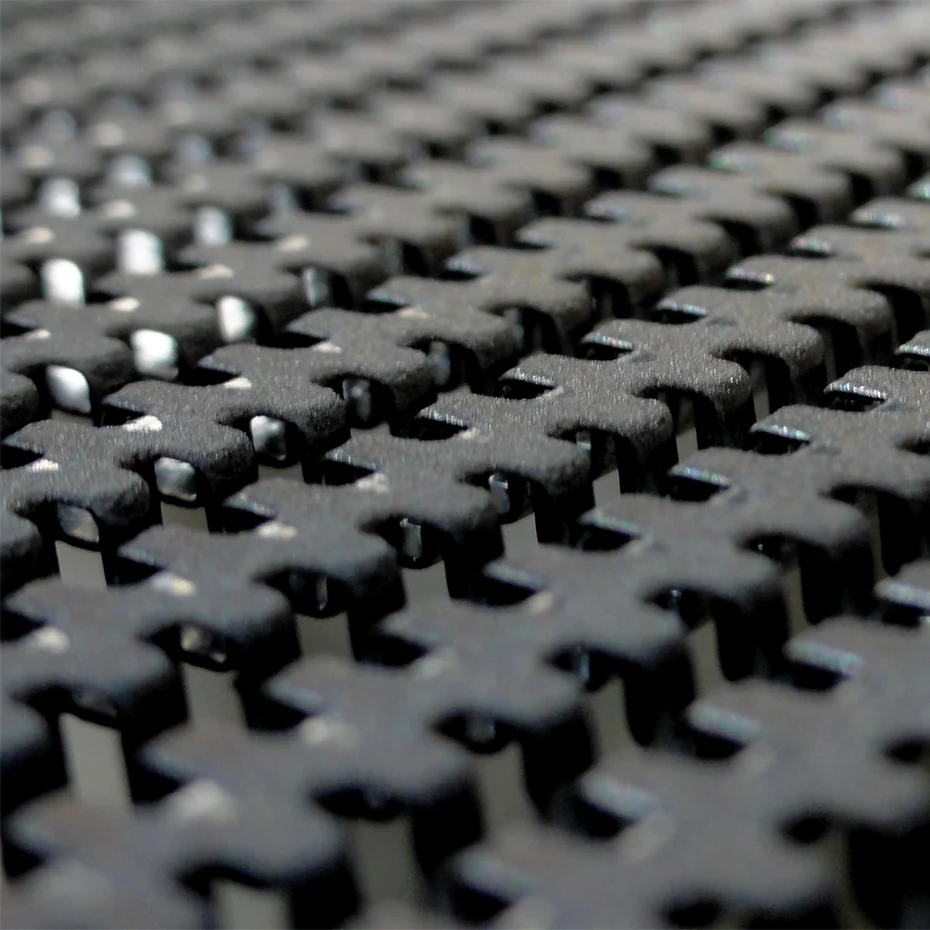

ローラコーティングは、正確で均一な量のろう材を油冷却フィンに効率的に塗布するために使用されます。Höganäs ローラコーティング専用ろう材 BrazeLet F300R-8501 は、必要な部分のみをコーティングしながら、最大 20 m/min のベルト速度で使用できます。これにより、重量の増減や各コンポーネントのコストが抑えられ、無駄がなくなり、より持続可能なソリューションが実現します。

ローラコーティングでペーストはペーストフィーダーを通りローラの表面に付着します。層の厚さはスクレイパーにより調整されます。ペーストをローラーからフィン先端またはフィンプレートに塗布する為、対象部品はローラの下をベルトで通過します。

新しい技術による品質の向上

エンジンオイルは、可動部品の潤滑、腐食防止、シーリングの改善、エンジンの冷却に使用される。エンジンオイルの寿命を縮める要因は数多くあります。例えば、エンジンオイルに含まれる不純物の量や、オイルが作動する温度などです。オイルの温度が低すぎると、含水量が高くなりすぎ、エンジンが損傷する恐れがあります。オイルの温度が高すぎると、オイルの劣化が早まり、交換の頻度も高くなります。そのため、すべての燃焼エンジンはオイルクーラーを使用して、オイルの寿命を延ばし、エンジンの摩耗を低減します。従来、大型車両で使用されるオイルクーラーは、銅ろうでろう付けされたステンレス鋼で製造されています。エンジンオイルには硫黄含有不純物、および場合によっては硫黄含有添加剤があり、銅と反応してさまざまな種類の硫化銅および硫酸銅を形成することがあるため、これが問題になる可能性があります。これらの銅の形成は、オイルの寿命と全体的な品質に悪影響を及ぼす可能性があります。

プライバシー保護に関する方針

私は、ヘガネスが、私と連絡をとる目的で、私の個人データを利用することに同意します。 また、私の連絡先情報をニュースレターやその他関連情報といったマーケティング目的に使用することに同意します。 データが第三者と共有されることはありません。 また、16歳以上であることを認めます。

個人情報の取扱いに関する詳細は、弊社のプライバシー保護方針でご確認いただけます。