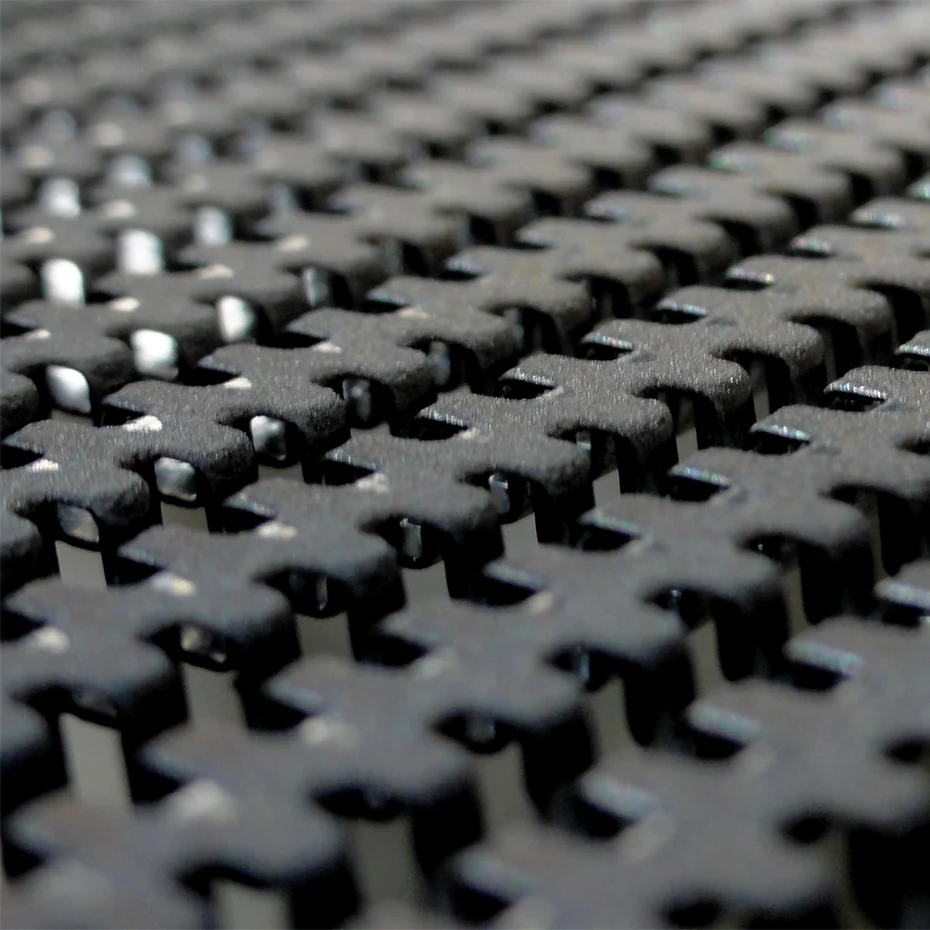

With Höganäs BrazeLet® F300, a patented stainless steel brazing filler material, it is possible to braze oil coolers completely copper-free. Zero ppm copper leaching to the engine oil results in increased oil lifetime and minimising wear on the engine. Better yet, it produces a product made entirely from stainless steel, which is easier to recycle, promoting sustainability in every way. Oil cooler turbulators can be efficiently coated with paste using roller coating which produces even coating layers with up to 20m/min belt speeds using Höganäs’ own developed paste, specially formulated for the roller coating process.

Höganäs oil cooler solution

Roller coating can be used to efficiently coat oil cooler fins with precise amounts of brazing filler material. Höganäs roller coating solution BrazeLet F300R-8501 enables usage of belt speeds up to 20 m/min without any problems, whilst only coating the parts where it is needed. This leads to a reduction in weight as well as the cost of every component, promoting zero waste and a more sustainable solution.

In roller coating, a paste roller moves through a paste reservoir and absorbs paste to its surface while scrapers adjust the layer thickness. To transfer the paste from the roller to the fin tip or fin plateau, the component is fed on a belt underneath the paste roller.

New technology increase quality

Engine oil is used to lubricate moving parts, inhibit corrosion, improve sealing and cool the engine. There are many factors that decrease the lifetime of engine oil, such as the amount of impurities it contains and at which temperature it is operating. If the temperature of the oil is too low, the moisture content is too high which can lead to engine damage. If the temperature of the oil is too high, the oil is degrading faster and needs to be changed more often. For this reason, all combustion engines use oil coolers to increase the lifetime of the oil and decrease wear on the engine. Traditionally, the oil coolers that are used in heavy-duty vehicles, are made out of copper-brazed stainless steel. This can be problematic because the engine oil holds sulphur-containing impurities and sometimes sulphur-containing additives, which can react with copper to form different kinds of copper-sulphides and copper-sulphates. These copper formations can be detrimental to the oil lifetime and overall quality.

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.