ArcX technology centres

Our services

At Höganäs, we believe the maximised application performance comes from the combination of the right material and the right process. By working with us, you will have complete access to our world-class product portfolio, multitude process, and application knowledge to identify the best coating application solutions for your needs.

At Höganäs, we believe the maximised application performance comes from the combination of the right material and the right process. By working with us, you will have complete access to our world-class product portfolio, multitude process, and application knowledge to identify the best coating application solutions for your needs.

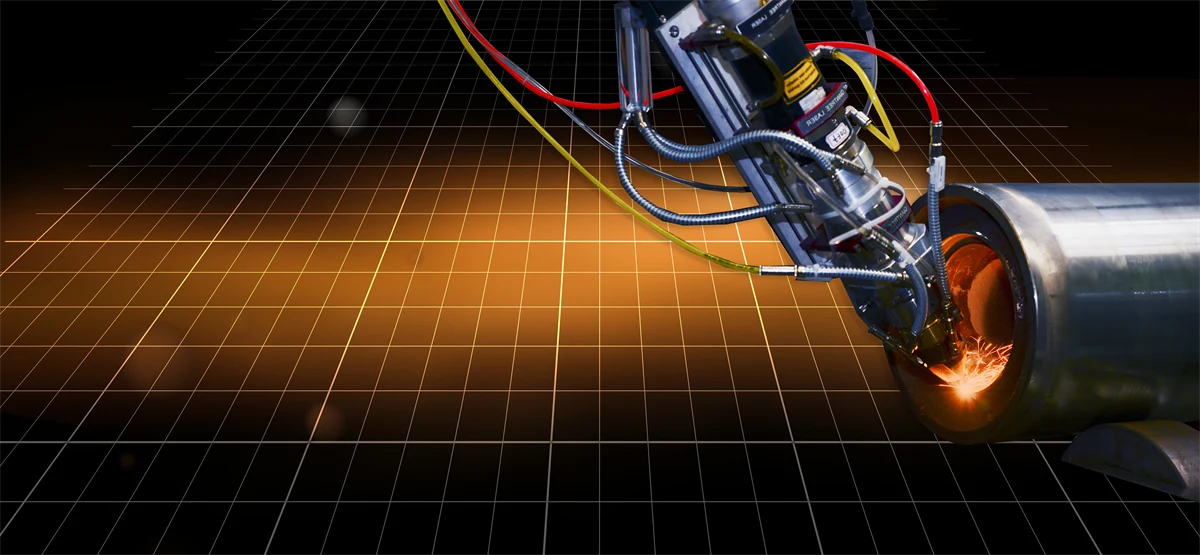

Coating development in ArcX

Our experts specialising in materials, processes, and customer applications make ArcX a unique development partner with full end-to-end knowledge. From concept development, prototyping, and process optimisation to taking them to the market. We provide you with the right material, for the right process to the right application.

Focus on customer satisfaction

Application development to design the right solution for your needs

- Pre-analysis: examine service conditions (operating environment, equipment, temperature, substrate properties) and coating requirements (wear and corrosion properties, clearance control, thermal insulation, etc)

- Concept creation: identify the relevant chemical composition and coating properties

- Prototyping: sample coatings, pilot production, and test for industrial production

- Coating analysis: process feasibility examination (smoothness, weldability, efficacy), coating performance evaluation (physical, mechanical, wear and corrosion properties)

Process optimisation to enhance coating performance

- Process support: Guidance in finding the right process parameters for coating applications

- Problem solving: On-site troubleshooting and failure analysis to solve operational challenges

Provide training to build a more professional workforce

- Continuous learning: Tailored to specific needs, ArcX brings specialists to conduct seminars and workshops in materials, applications, processes, and industry knowledge. Either at ArcX facilities, or on site at customers and end users.

Material development and innovation

We research and develop next-generation material solutions tailored to both new and existing coating demands and trends. The concept from material innovation will be further validated by our ArcX surface coating technology centres. Every day, our first-in-class experts specialise in material science and engineering work across the world, connecting with external partners, customers, and end users to bring the best thinking and ideas together, then put them into practice.

Data-driven approach to develop new material concepts

With our multi-scale material modelling experts predicting the physical, mechanical, wear and corrosion properties of new products, we are capable of applying ICME (Integrated Computational Material Engineering) for generating new product concepts. Instead of extensive traditional empirical alloy experimentations, we first screen out the most optimal solutions through materials genomic databases and process structure modelling and simulation, then proceed to practical experiments with time and cost efficiency.

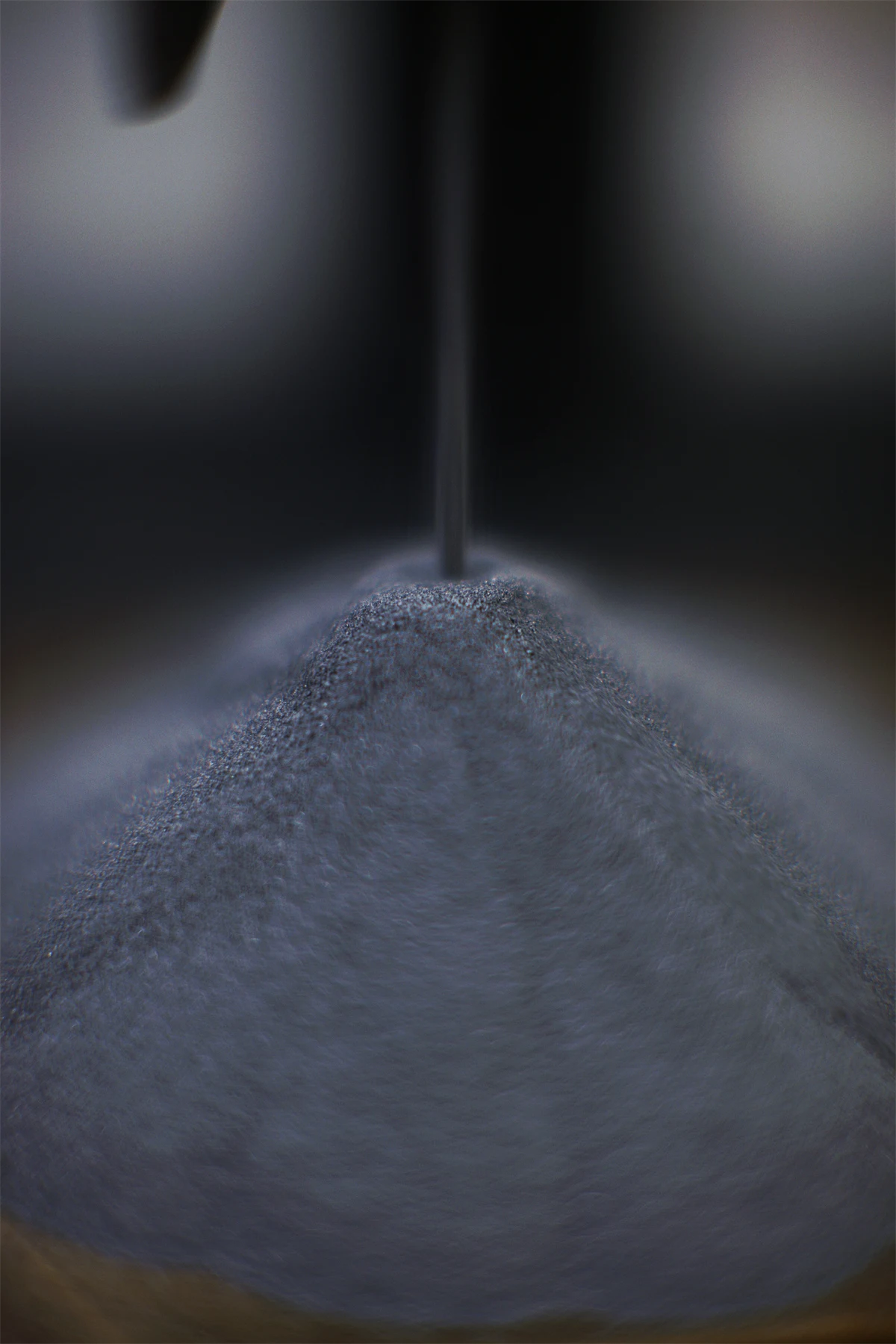

Translate science into product through powder engineering

Thanks to our world-class manufacturing process and material characterisation and analysis experts, we produce the pilot powder based on the new material concept. Then we test and validate the new material whether it could fulfil defined physical, mechanical, wear and corrosion property requirements for the target application in ArcX.

Scale-up validation to achieve industrial production

We are pushing the boundaries with continuous progress while optimising the material for real-life production. The collaboration between product development experts and manufacturing process experts, as well as the high-quality and consistent production route ensure the new materials are of the same properties and qualities in the industrial production environment as we had in the pilot test, with less operating cost and increased productivity. We are striving to create new materials that can achieve the best thinking and ideas in our vision for industrial production.

Datenschutzerklärung

Ich bin damit einverstanden, dass Höganäs meine personenbezogenen Daten dafür nutzt, Kontakt mit mir aufzunehmen. Meine Kontaktdaten können auch zu Marketingzwecken verwendet werden, beispielsweise für Newsletter und andere relevante Informationen. Die Daten werden nicht an Dritte weitergegeben. Mit meiner Einwilligung bestätigte ich außerdem, dass ich älter als 16 Jahre bin.

Weitere Informationen über unseren Umgang mit personenbezogenen Daten sind in unserer Datenschutzerklärung zu finden.