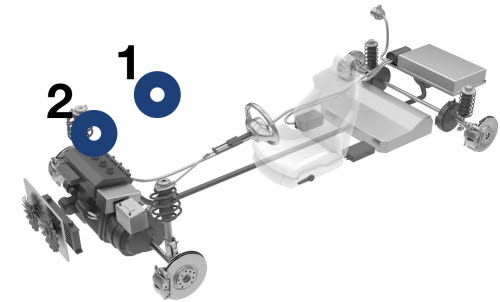

1. Engine

2. Transmission

3. Body and chassi

Hybrid cars

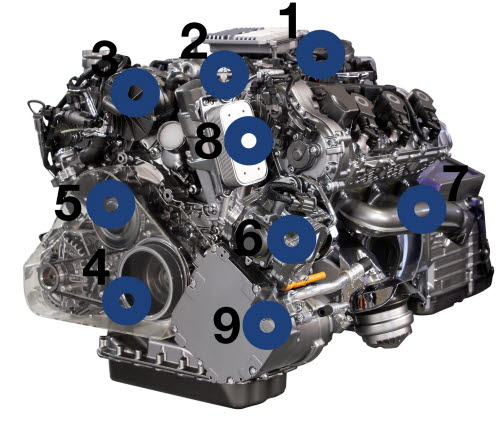

Engine

- Fuel injection

- Ingnition systems

- Pumps

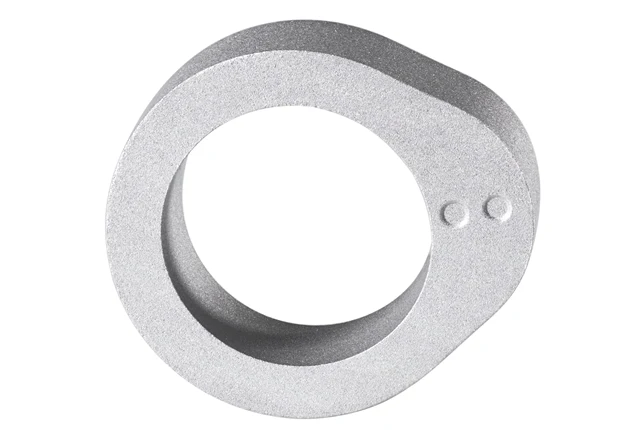

- Crankshaft

- Valventrain

- A/C compressor

- Exhaust gas reciculation (EGR) cooler

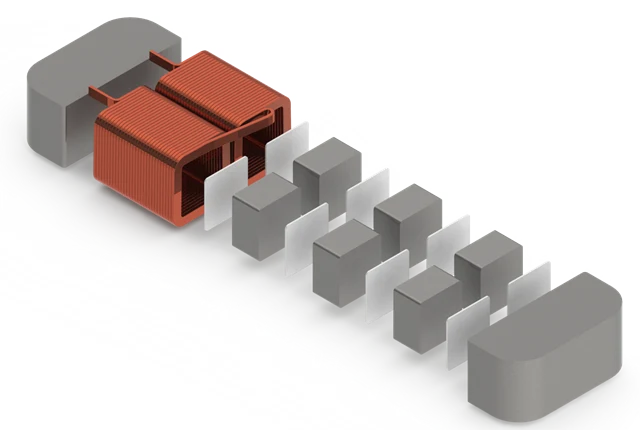

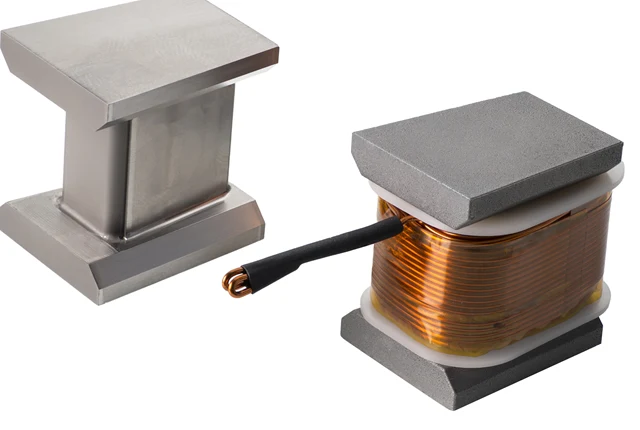

- DC/DC reactor

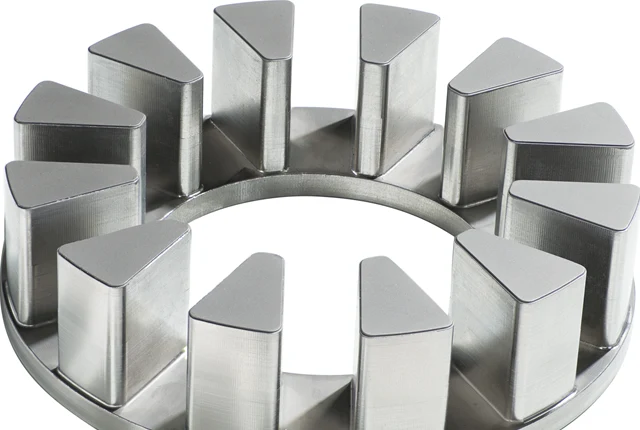

- Electric motors

Cost and weight are the two most vital factors when designing the drivetrain in hybrid cars. When optimising these factors, a manufacturer can enhance fuel efficiency, improve performance and lower manufacturing costs. Another fundamental factor is achieving complex geometries of crucial components that might be challenging to obtain with traditional manufacturing methods.

Sprockets, such as crank- and camshaft sprockets, are commonly used in hybrid engine systems and often have precise tooth profiles. They require high strength and durability, which powder metallurgy can provide.

By making core components in A/C compressors and DC-DC converters of soft magnetic composites, manufacturers can obtain small and lightweight systems with high efficiency.

Höganäs’ brazing technology for cooling system components helps in creating lightweight yet durable components for efficient cooling.

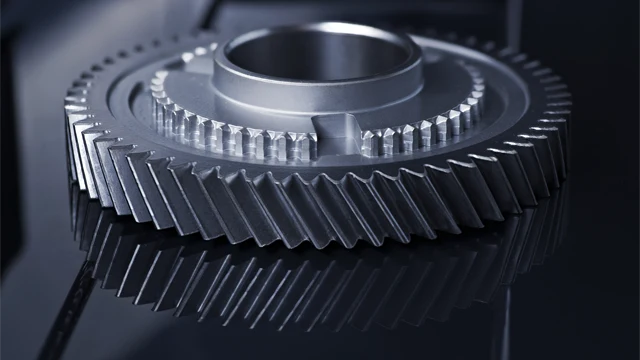

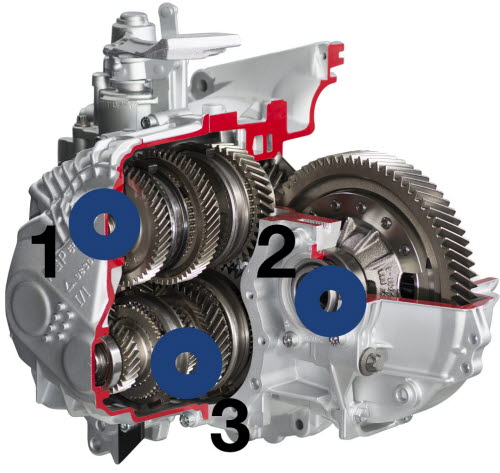

Transmission

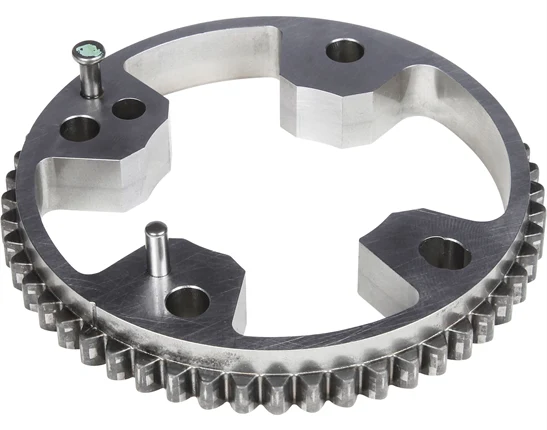

- Transfer case sprockets

- Planetary carriers

- Differential gears

Sintered gears are crucial components in the transmission system of a hybrid engine. Transfer case sprockets, planetary carriers and differential gears are examples of suitable applications for using powder metal technology.

Sintering allows the production of complex-shaped gears with high precision, making them suitable for efficient power transmission. Another benefit with PM components is the efficient use of materials, minimising waste and reducing overall production costs. A third advantage is enhanced mechanical properties, wear resistance and durability.

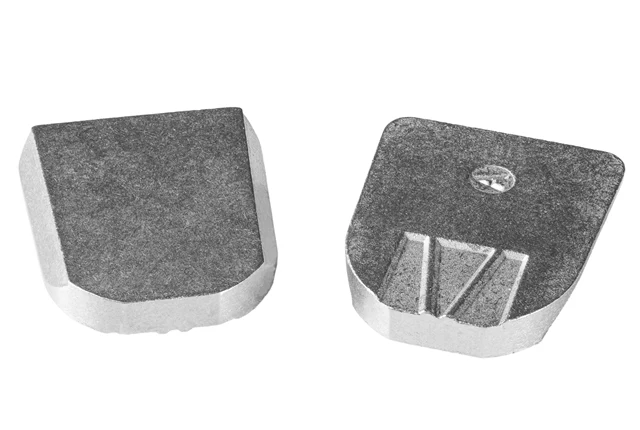

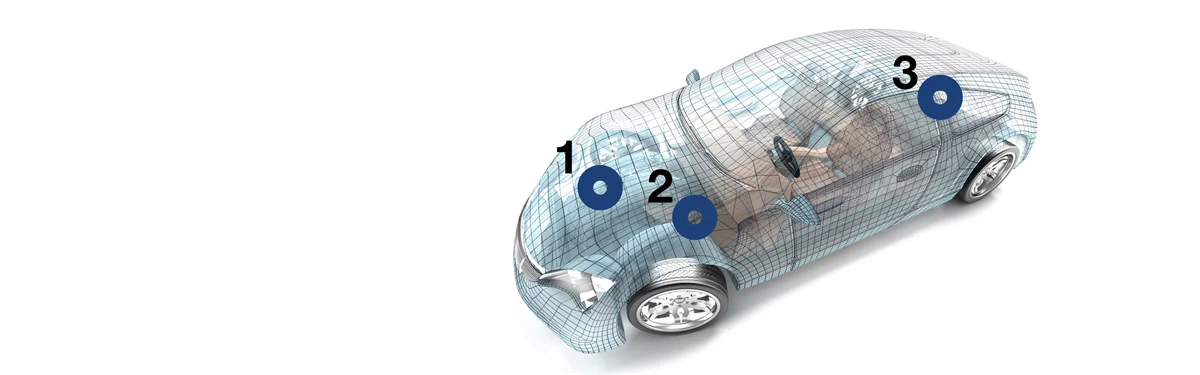

Body and chassi

- Mirrors

- Shock absorbers

Höganäs is a key player in facilitating high-volume production of vital components subjected to continuous heavy loads. Sintered parts, including shock absorber rods, shock absorber pistons and mirror bosses, provide increased strength and durability, significantly enhancing the general sturdiness of a car’s body and chassis.

The meticulous manufacturing process of the pressing and sintering technology enables design engineers to create intricate designs and complex shapes, which optimises structural efficiency while minimising material waste. This precision in production underscores the advantages offered by sintered parts in achieving both performance excellence and resource efficiency in automotive applications.

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.