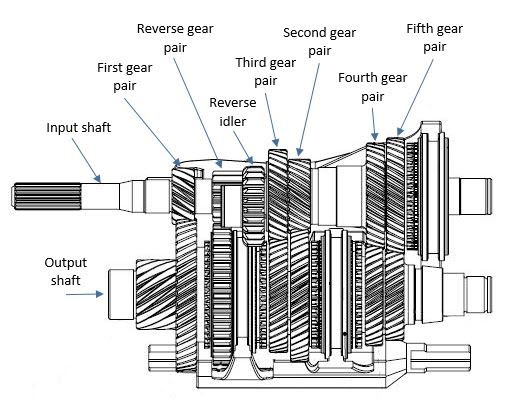

The Smart project was done in collaboration with North American KBE+, a gear design consultancy firm, and consisted of a teardown and redesign of the transmission in a 2008 Smart ForTwo. The car is small, only 2.7 meters long and weighs in at a modest 820 kg. However, the engine still pumps out decent power at 70HP and 92.2Nm torque! All that power is handled by a 5-speed AMT, a manual transmission with servos handling both shifting and the clutch. The layout of the transmission can be seen in the illustration below.

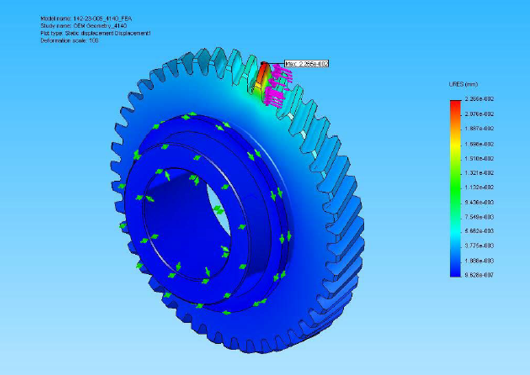

After the teardown and subsequent measuring and analyzing of the gears, a transmission model was created and used to make PM optimized gear designs. Seven gears in total were converted to PM, some gears like the first and second input gears were machined on the input shaft and hence not possible to convert. The material of choice was Astaloy 85 Mo with 0.3 % graphite, a well-known and commonly used material within the PM industry.

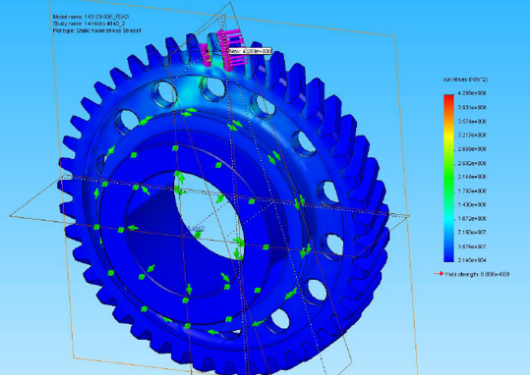

A gear in the Smart transmission before and after PM optimization.

Designing gears for PM is really not that much different compared to designing gears for solid steels. The material parameters differ depending on the material composition, density and secondary operations like heat treatment or surface densification. Höganäs makes these parameters complete with SN curves available for partners interested in PM gears. All this data along with power transfer requirements and required service life is put into a gear design software by a transmission design engineer and out comes a gear optimized for PM. Additionally, PM offers additional design freedom such as tooth root design that in conventional gear cutting is decided by the cutting motion of the hob that cuts the gear teeth and can’t be modified. With PM an optimal root shape can be used that enables a stress reduction in the gear tooth root, we have seen stresses lowered by 40% in some cases.

In total, a weight saving of 15.0% and a reduction in inertia of 14.9% was possible through a combination of weight saving design and lower density of the PM gears over the OEM cut steel gears. All PM gears were manufactured from compacted and sintered blanks using conventional gear cutting processes. The cut gears were then heat treated using gas carburization and oil quenching before finish grinding. Due to the internal porosity of not fully dense PM, standard steel heat treatment recipes can’t be used, the carburizing gas travels much faster into the PM part and shorter cycle times are therefore needed.

A complete transmission with the seven PM optimized gears was built and mounted in a Smart ForTwo. The car was then driven around Europe and shown to the transmission design community to open their eyes to the wonders of PM! This was just the first of many transmission gear projects that soon followed at Höganäs and the Smart ForTwo lost its place in the spotlight, and was soon forgotten. However, one of Höganäs employees have been diligently commuting to work with the little car and managed to put over 200.000 km of wear on the transmission. After reaching 200.000 km the gearbox was taken out of the car and disassembled and when we opened it we were shocked to see…

Tune in to #InsightsByHoganas in the coming weeks to find out!