Chemical & Metallurgical

Powders for chemical and metallurgical processes

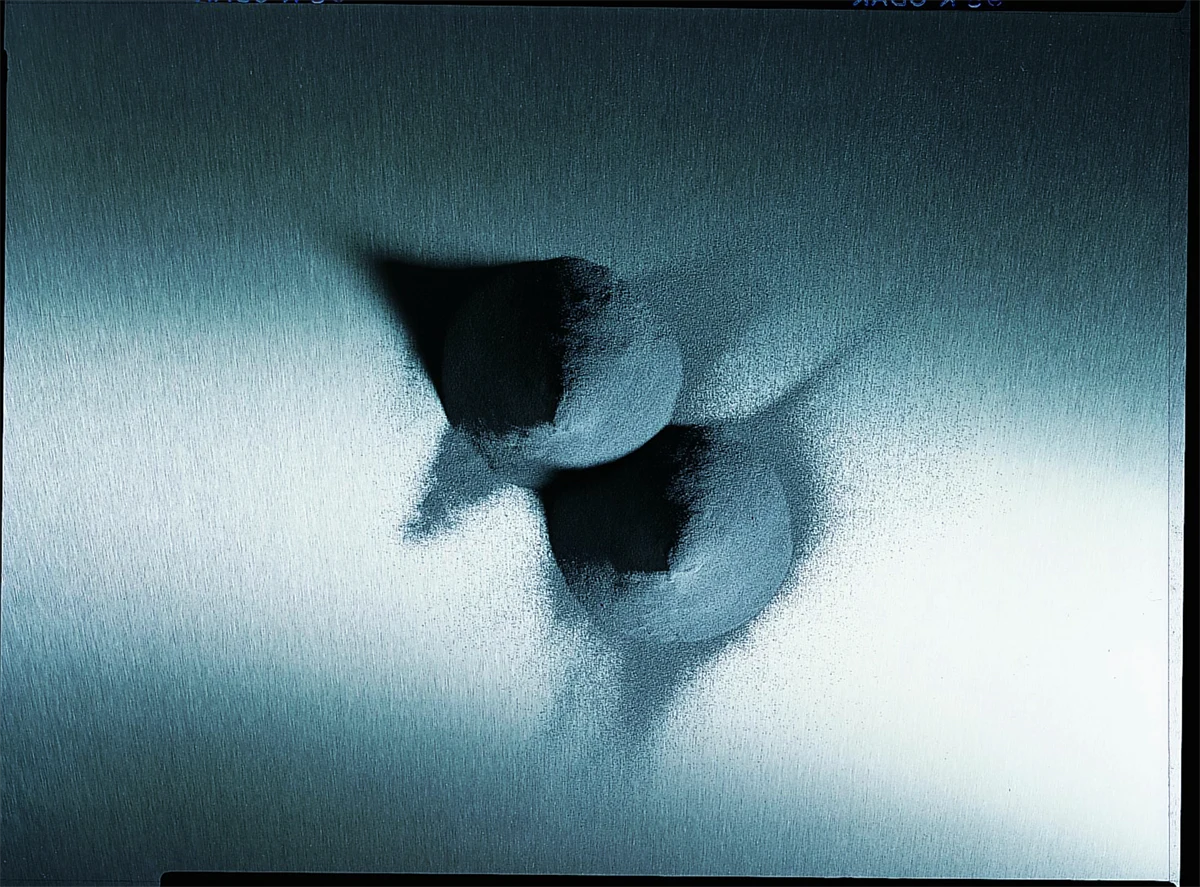

Iron powder is the best choice or even the only alternative in many applications that require specific properties and consistency. The high surface area and/or purity of iron powder offer more cost-effective solutions and increased productivity compared to alternative methods.

Application examples

- Addition to refractories or concrete

- Reduction and catalytic agent in organic/inorganic processes

- Diamond tools

- Hot bags

- Oxygen absorbers

- Raw material in production of organic/inorganic salts

- Pigments

- Alloying element

- Magnetic crack detection

- Melting stock in steel making

Our powders can also be used as additions to polymers to provide magnetic properties as well as to increase weight, heat conductivity or sound-absorption. There are many other application areas wherein iron powders are used.

Features and benefits

- Optimization of powders for the specific purpose of the applications.

- Widest range of powders having different apparent densities, particle sizes, surface areas, purities and morphologies to suit your specific needs.

- Cost-effective and tailor-made solutions.

- Mixing solutions on request.

Contact us for choosing the best suited grade of powder for your application

Höganäs market a wide range of products suitable for Chemical and Metallurgical applications.

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

You might also be interested in