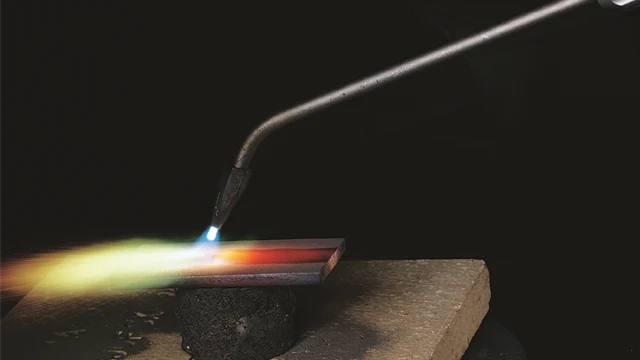

Flame spraying powders

Surfit® cobalt (Co) based powders

Surfit 2261-00 | Co 1.5C 3B 3Si 19Cr 1.75Fe 13.3Ni 0.45Cu 0.4Mn 15W | 106-36 µm

Particle size: 106/36 µm

Chemistry: Co 1.5C 3B 3Si 19Cr 1.75Fe 13.3Ni 0.45Cu 0.4Mn 15W

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 2348-00 | Co 2.3C 1.2Si 30Cr 1.3Fe 0.75Ni 0.45Cu 12.8W | 125/45 µm

Particle size: 125/45 µm

Chemistry: Co 2.3C 1.2Si 30Cr 1.3Fe 0.75Ni 0.45Cu 12.8W

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit® hard phase powders

Surfit Ni self-fluxing + Carbide mixes

Höganäs offers a wide range of Surfit powder mixes with Ni self-fluxing (SF) alloys and tungsten carbides.

With a broad portfolio of Ni self-fluxing alloys in combination with different tungsten carbides, we tailor mixes to meet the application requirements.

- Ni self-fluxing alloys

- Amperweld® Tungsten carbides

- Amperweld CTC - Cast Tungsten Carbides

- Amperweld SCTC - Spherical Cast tungsten carbide

- Amperweld MTC - Macroline Tungsten Carbide

- Amperit® Tungsten carbide cobalt

- Amperit 519 WC-Co 88-12

- Amperit 526 WC-Co 83-17

Please contact your local Höganäs sales representative to find a matching Surfit mix for your application.

Particle size: -

Chemistry: -

Powder type: Blended

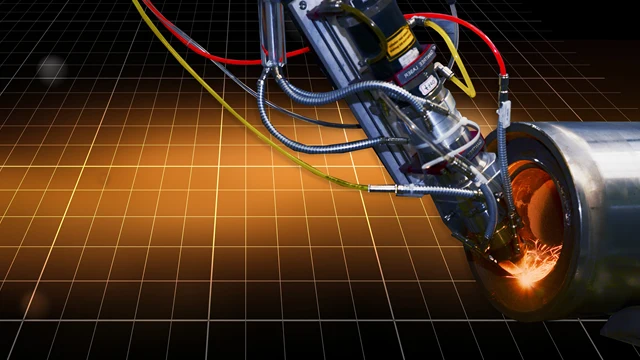

Typical deposition techniques: Flame spraying, HVOF, laser cladding, plasma transferred arc (PTA), powder welding

Amperit® nickel (Ni) based powders

Amperit 250.002 | Ni 20Cr | 90/45 µm

Particle size: 90/45 µm

Chemistry: Ni 20Cr

Powder type: Water atomised

Suitable for deposition techniques: Atmospheric plasma spraying (APS), flame spraying

|

Remarks:

|

||

Amperit 251.002 | Ni 20Cr | 90/45 µm

Particle size: 90/45 µm

Chemistry: Ni 20Cr

Powder type: Gas atomised

Suitable for deposition techniques: Atmospheric plasma spraying (APS), flame spraying

|

Remarks:

|

||

Amperit 280.002 | Ni 5Al | 90/45 µm

Particle size: 90/45 µm

Chemistry: Ni 5Al

Powder type: Water atomised

Suitable for deposition techniques: Atmospheric plasma spraying (APS), flame spraying

|

Remarks:

|

||

Amperit 281.002 | Ni 5Al | 90/45 µm

Particle size: 90/45 µm

Chemistry: Ni 5Al

Powder type: Gas atomised

Suitable for deposition techniques: Atmospheric plasma spraying (APS), flame spraying

|

Remarks:

|

||

Surfit® nickel (Ni) based powders

Surfit 1315-00 | Ni <0.06C 2Si 1.1B 0.5Fe 20Cu | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni <0.06C 2Si 1.1B 0.5Fe 20Cu

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1335-00 | Ni 0.15C 3.1Si 1.6B 1.8Fe 4.8Cr | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.15C 3.1Si 1.6B 1.8Fe 4.8Cr

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1335-40 | Ni 0.32C 3.7Si 1.2B 3Fe 7Cr | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.32C 3.7Si 1.2B 3Fe 7Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1240-00 | Ni 0.25C 3.5Si 1.6B 2.5Fe 7.5Cr | 106/36 µm

Particle size: 106/36 µm

Chemistry: Ni 0.25C 3.5Si 1.6B 2.5Fe 7.5Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1340-00 | Ni 0.25C 3.5Si 1.6B 2.5Fe 7.5Cr | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.25C 3.5Si 1.6B 2.5Fe 7.5Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1245-00 | Ni 0.35C 3.6Si 1.9B 2.7Fe 9Cr | 106/36 µm

Particle size: 106/36 µm

Chemistry: Ni 0.35C 3.6Si 1.9B 2.7Fe 9Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1345-00 | Ni 0.35C 3.6Si 1.9B 2.7Fe 9Cr | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.35C 3.6Si 1.9B 2.7Fe 9Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1250-00 | Ni 0.45C 3.8Si 2.2B 2.9Fe 11Cr | 106/36 µm

Particle size: 106/36 µm

Chemistry: Ni 0.45C 3.8Si 2.2B 2.9Fe 11Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1350-00 | Ni 0.45C 3.8Si 2.2B 2.9Fe 11Cr | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.45C 3.8Si 2.2B 2.9Fe 11Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1250-20 SP239 | Ni 0.5C 4Si 2.4B 3.1Fe 11.3Cr | 106/36 µm

Particle size: 106/36 µm

Chemistry: Ni 0.5C 4Si 2.4B 3.1Fe 11.3Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1255-20 | Ni 0.55C 4Si 3.4B 2.7Fe 16Cr 3Mo 3Cu | 106/36 µm

Particle size: 106/36 µm

Chemistry: Ni 0.55C 4Si 3.4B 2.7Fe 16Cr 3Mo 3Cu

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1355-20 | Ni 0.55C 4Si 3.4B 2.7Fe 16Cr 3Mo 3Cu | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.55C 4Si 3.4B 2.7Fe 16Cr 3Mo 3Cu

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1359-40 | Ni 0.02C 3Si 2.9B 0.2Fe | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.02C 3Si 2.9B 0.2Fe

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1260-00 | Ni 0.75C 4.3Si 3.2B 3.8Fe 14.8Cr | 106/36 µm

Particle size: 106/36 µm

Chemistry: Ni 0.75C 4.3Si 3.2B 3.8Fe 14.8Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1360-00 | Ni 0.75C 4.3Si 3.2B 3.8Fe 14.8Cr | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.75C 4.3Si 3.2B 3.8Fe 14.8Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1360-20 | Ni 0.9C 4.3Si 3.3B 4.2Fe 16.3Cr | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.9C 4.3Si 3.3B 4.2Fe 16.3Cr

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1362-10 | Ni 0.6C 3.7Si 2.8B 3.5Fe 14.3Cr 9.5W | 125/45 µm

Particle size: 125/45 µm

Chemistry: Ni 0.6C 3.7Si 2.8B 3.5Fe 14.3Cr 9.5W

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 72-W-40 | Ni 0.35C 3.1Si 1.7B 3.2Fe 9.9Cr | -150/+325 mesh

Particle size: -150/+325 mesh

Chemistry: Ni 0.35C 3.1Si 1.7B 3.2Fe 9.9Cr

Powder type: Water atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 72-M-40 | Ni 0.35C 3.1Si 1.7B 3.2Fe 9.9Cr | -150/+325 mesh

Particle size: -150/+325 mesh

Chemistry: Ni 0.35C 3.1Si 1.7B 3.2Fe 9.9Cr

Powder type: Water atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 74-W-60 | Ni 0.58C 4.1Si 2.9B 4.4Fe 13.6Cr | -150/+325 mesh

Particle size: -150/+325 mesh

Chemistry: Ni 0.58C 4.1Si 2.9B 4.4Fe 13.6Cr

Powder type: Water atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 74-M-60 | Ni 0.58C 4.1Si 2.9B 4.4Fe 13.6Cr | -150/+325 mesh

Particle size: -150/+325 mesh

Chemistry: Ni 0.58C 4.1Si 2.9B 4.4Fe 13.6Cr

Powder type: Water atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 76-W-50 | Ni 0.55C 3.7Si 2.4B 4.1Fe 13.3Cr | -150/+325 mesh

Particle size: -150/+325 mesh

Chemistry: Ni 0.55C 3.7Si 2.4B 4.1Fe 13.3Cr

Powder type: Water atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 76-M-50 | Ni 0.55C 3.7Si 2.4B 4.1Fe 13.3Cr | -150/+325 mesh

Particle size: -150/+325 mesh

Chemistry: Ni 0.55C 3.7Si 2.4B 4.1Fe 13.3Cr

Powder type: Water atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 80-W-60 | Ni 0.60C 4.2Si 3.9B 4.6Fe 14Cr 2.5Mo 2.4Cu | -150/+325 mesh

Particle size: -150/+325 mesh

Chemistry: Ni 0.60C 4.2Si 3.9B 4.6Fe 14Cr 2.5Mo 2.4Cu

Powder type: Water atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 80-M-60 | Ni 0.60C 4.2Si 3.9B 4.6Fe 14Cr 2.5Mo 2.4Cu | -150/+325 mesh

Particle size: -150/+325 mesh

Chemistry: Ni 0.60C 4.2Si 3.9B 4.6Fe 14Cr 2.5Mo 2.4Cu

Powder type: Water atomised

Typical deposition techniques: Flame spraying

|

Remarks:

|

||

Surfit 1216-5270 | Ni <0.15C 19.5Cr 0.7Mn 1Si | 106/20 µm

Particle size: 106/20 µm

Chemistry: Ni <0.15C 19.5Cr 0.7Mn 1Si

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

Surfit 5210-40 | Ni 5Al | 106/20 µm

Particle size: 106/20 µm

Chemistry: Ni 5Al

Powder type: Gas atomised

Typical deposition techniques: Flame spraying

Surfit Ni self-fluxing + Carbide mixes

Höganäs offers a wide range of Surfit powder mixes with Ni self-fluxing (SF) alloys and tungsten carbides.

With a broad portfolio of Ni self-fluxing alloys in combination with different tungsten carbides, we tailor mixes to meet the application requirements.

- Ni self-fluxing alloys

- Amperweld® Tungsten carbides

- Amperweld CTC - Cast Tungsten Carbides

- Amperweld SCTC - Spherical Cast tungsten carbide

- Amperweld MTC - Macroline Tungsten Carbide

- Amperit® Tungsten carbide cobalt

- Amperit 519 WC-Co 88-12

- Amperit 526 WC-Co 83-17

Please contact your local Höganäs sales representative to find a matching Surfit mix for your application.

Particle size: -

Chemistry: -

Powder type: Blended

Typical deposition techniques: Flame spraying, HVOF, laser cladding, plasma transferred arc (PTA), powder welding

Amperit® pure metals, alloys & other material powders

Amperit 250.002 | Ni 20Cr | 90/45 µm

Particle size: 90/45 µm

Chemistry: Ni 20Cr

Powder type: Water atomised

Suitable for deposition techniques: Atmospheric plasma spraying (APS), flame spraying

|

Remarks:

|

||

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.