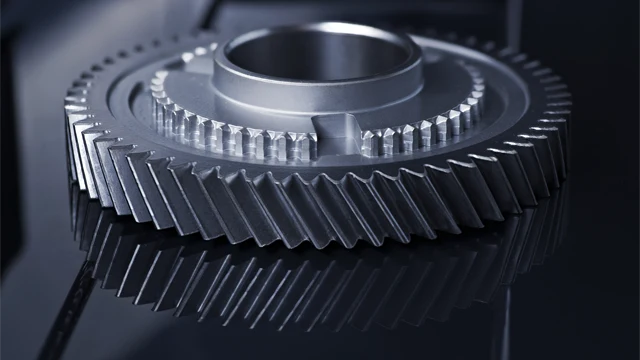

Crankshaft bearings caps (also known as main bearing caps) are subject to heavy loads and need to be extremely crack-resistant. Choosing powder metallurgy (PM) over an alternative manufacturing process provides excellent near net-shape geometry and fatigue resistance and eliminates preassembly machining steps. PM bearing caps usually require only one line-boring step during installation, which translates into a substantial cost saving.

Höganäs machining enhancers further reduce production cost by providing excellent machinability of line-boring after pre-assembly, which reduces tool wear.

|

Benefits of Höganäs’ solution for PM bearing caps:

|

||

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.