Sintering expert services

Your partner for improving your sintering process

Material data

We help you generate material data for various sintering conditions to help you choose the most suitable material and processing conditions.

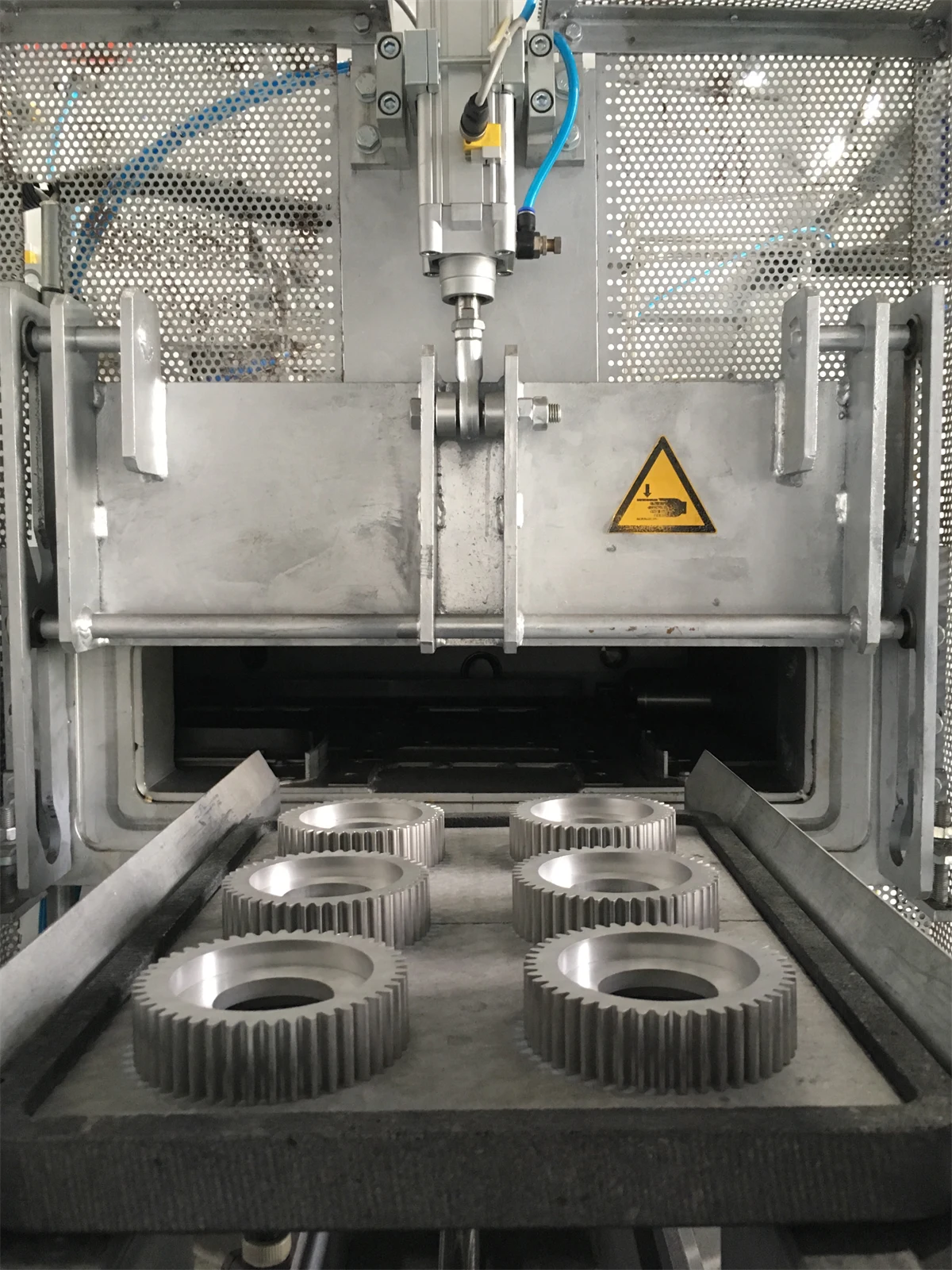

Prototype sintering

We offer you prototype sintering capabilities at various conditions to optimise your sintering process and achieve required material performance at lowest total cost.

On-site furnace measurements

We offer furnace measurements at your site to evaluate your sintering conditions and propose means to maximise your sintering efficiency. We can evaluate the following:

- Oxidation

- Carburisation/decarburisation

- Dewaxing conditions

- Leaking

- Sooting/blistering

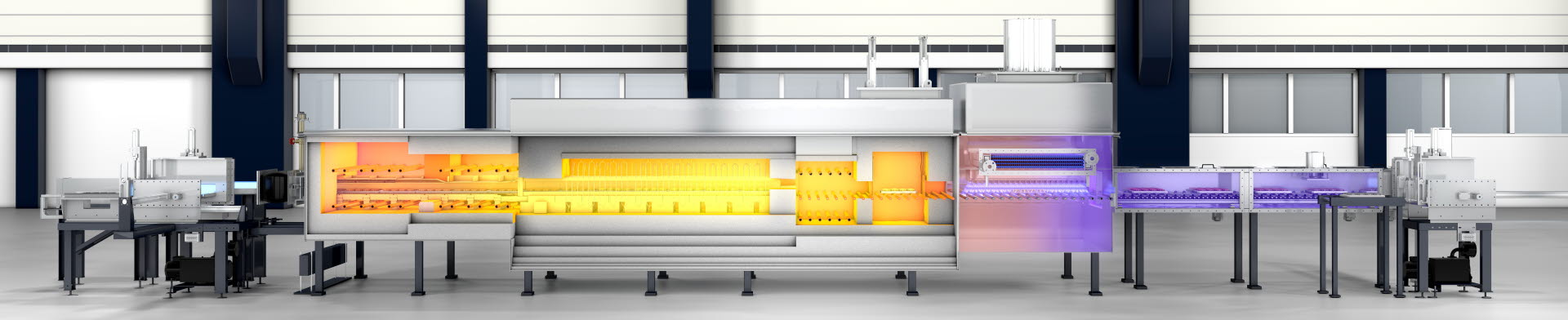

| Equipment | Capacity | Application |

|

High-temperature |

1360 °C max, 6 °C/s cooling rate, |

Pilot scale high temperature sintering suitable for component prototyping, as well as test specimens. Sinter-hardening capabilities. |

| Belt furnace |

1150 °C max, N2/H2, |

Standard sintering conditions for testing bars and measurement. |

| SMC belt furnace |

800 °C max, air, N2, steam, +/- 3 °C temp stability, 120 kg/h max load |

Heat treatment of all three Somaloy grades (1P, 3P, 5P) |

| Tube furnace |

1200 °C max in vacuum, |

Stainless steel and other alloy sintering at vacuum conditions. |

| Furnace |

1100 °C max, -0.1MPa vacuum, |

Low-temperature sintering and dewaxing process. |

| SinterFlex system |

CO, oxygen and, |

Online measurement of atmosphere quality in dewaxing, sintering, cooling zone and gas inlet. |

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.