Deposition techniques

Consistent results with laser cladding

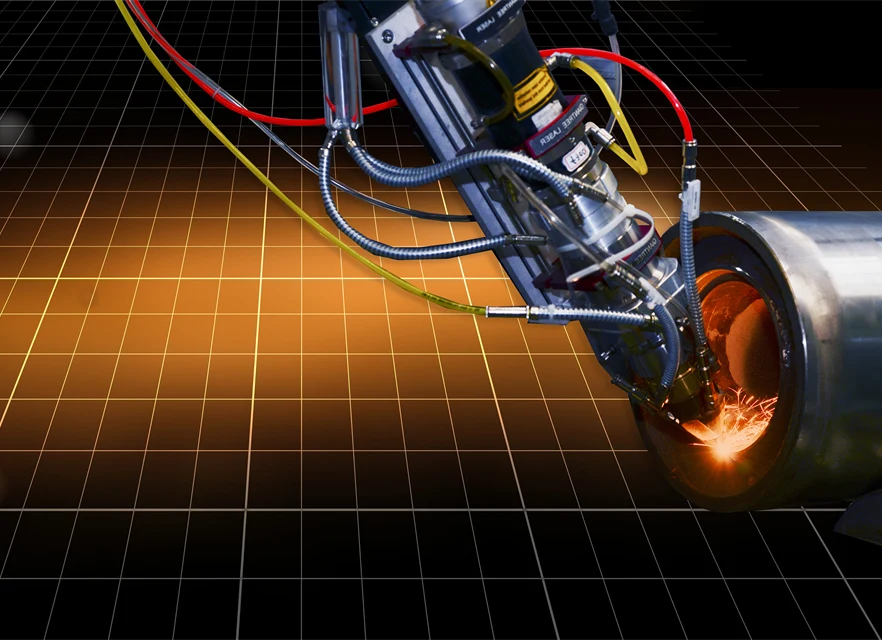

With laser cladding, which is also known as laser metal deposition, metal powder is fed into a melt pool generated by a laser beam. The melted material is deposited accurately and with minimal heat to the underlying substrate.

Laser cladding enables a metallurgical bonding with the base material substrate, like in case of PTA surface welding. The overlays can be applied to most Fe and Ni based substrates with some exceptions.

A high-energy laser beam creates an intense heat input and thus alloys are bonded to the surface with a low degree of dilution (<5%). Laser cladding can be fully automated and once the parameters are fixed for a certain design, the final results are consistent for all parts.

The laser cladding process is used to improve wear resistance and to repair worn or damaged surfaces. It is a flexible process since it is possible to mix two or more powders at the same time as the feed rate is separately controlled for both feed streams.

Typical working range

Typical working range

- Deposition rate: up to 8 kg/hour

- Deposition thickness: 0.5 - >4 mm

- Deposition hardness: up to 68 HRC

Benefits

- Suitable for automation

- No fusing required

- 0.5->4 mm thickness

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

ArcX coating hub

ArcX – Your starting point for innovation

Expert know-how in materials, surface welding and flame spraying processes and customer applications make our ArcX technology centres an exclusive resource in your work to optimise existing applications and develop new business opportunities.